Overview

Today, the debate surrounding energy issues and environmental issues has started to be heard in global politics and economics. Humankind’s reliance on petroleum as an energy source has led to fears of its depletion, and the carbon dioxide released when it is burned has been cited as one cause of global warming. Either way, this is a major problem that can affect the destiny of the entire world. This is why there are growing calls for environmentally-friendly clean energy to resolve these problems.

Electric power has attracted attention as one answer to this problem. Fuel cells generating power using hydrogen and solar cells generating power using the sun’s rays are seen as important devices for contributing to reduced carbon dioxide emissions, and demand for these devices continues to grow. As these devices move to mass production, improving their energy-generating performance is not the sole issues. Instead, other issues arise, including reducing the environmental burden of the cell manufacturing process itself and boosting the performance of manufacturing equipment for cutting energy waste. Furthermore, the collection of used devices and their reuse must also be considered for coming even closer to realizing the ideal clean energy.

On the other hand, in manufacturing sites, the “surface” of various materials holds an important role. For example, in corrosion-resistant materials, prevention of surface rust is used to block damage to the interior.Developing material surfaces with functions can enable higher performance and value for materials and reduce waste of resources. Materials for fuel cells and solar cells are no exception.

We are conducting research in advanced surface technology for enabling the creation of environmentally-friendly materials using environmentally-friendly processes.

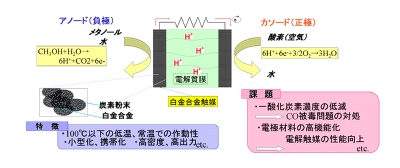

I. Research on Development of Catalysts for Fuel Cells

Fuel cells are devices that use an electro-chemical reaction to generate electricity from hydrogen. Hydrogen can be derived from a wide variety of materials including natural gas, methanol, and biomass gas, and because carbon dioxide is not released during the power generation process, fuel cells can truly be called environmentally-friendly. Direct methanol fuel cells have the advantages of high output, high efficiency, low activation temperature (less than 100°C), and ease of designing in a compact size, and they have already been adopted for use as power supplies for mobile devices and fuel cell automobiles. Enhanced functional electrode materials are essential for realizing further improvements in activation capability and compact designs. We are conducting research in new manufacturing processes for catalysts that support platinum alloy on carbon powder surfaces.

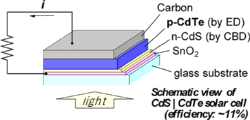

Ⅱ.Research on Electrodeposition of New Functional Thin Films

Solar cells generate power using a photovoltaic effect where current flows when light shines on an internal semiconductor. Currently, silicon is a widely-used material for solar cells, but research is being conducted on the use of other materials for providing even higher energy efficiency. We are researching the creation of functional compound material thin films by using deposition of compound semiconductor thin films for solar cells and composite coatings by codeposition of metal and ceramic microparticles.

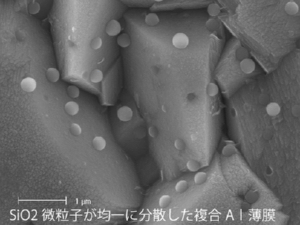

Ⅲ.Research on Development of New Functional Surface Treatment Techniques

Today, zinc plating is widely used for surface treatment of steel and metal materials. There are concerns, however, about the depletion of zinc resources in the future, and so the development of zinc minimization techniques has been gaining momentum. Research is proceeding on a wide range of treatment techniques that enable the application of zinc using even smaller amounts, thinner and stronger coatings, and in more complex shapes. We are currently developing a new aluminum alloy plating technique using our own non-aqueous solvent as one possible candidate.

Composite Al coating with a uniform dispersion of SiO2 microparticles

Composite Al coating with a uniform dispersion of SiO2 microparticles

Ⅳ.Research on Aqueous Processing for Materials

Material processes using aqueous solution are environmentally-friendly energy-saving processes that can be performed at room temperature. In the future, we will be conducting research on rare metal recycling processes using aqueous solution and new material manufacturing processes.